龍燡企業有限公司成立於2007年,專注各式精密零件組件設計開發及複合材料研究,並提供精密測量、 精密加工、及ODM / 逆向工程等服務,涉及各式特殊材料,如石墨、石英、工程塑膠、及各式陶瓷,於2018年導入X-Ray量測服務及三次元和2.5D共同測量系統,以確保出貨品質及提升產品在開發階段的精確性。

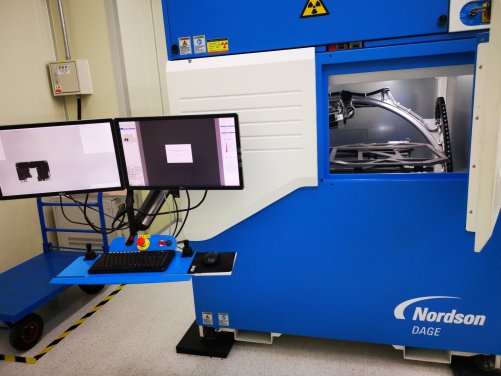

每一件龍燡產品都會經過我們的精密測量系統。 以確保每一件產品都能滿足客戶對產品公差的需求。 我們的精密測量工具是 X 射線測量系統、2.5D 圖像測量和坐標測量機。 每種測量方式都有不同的方便或準確。 為了測量出最詳細、最準確的數據,龍燡將選擇最合適、最準確的精密測量並且在測量後,我們的系統可以為客戶提供詳細的報告。

每一件龍燡產品都會經過我們的精密測量系統。 以確保每一件產品都能滿足客戶對產品公差的需求。 我們的精密測量工具是 X 射線測量系統、2.5D 圖像測量和坐標測量機。 每種測量方式都有不同的方便或準確。 為了測量出最詳細、最準確的數據,龍燡將選擇最合適、最準確的精密測量並且在測量後,我們的系統可以為客戶提供詳細的報告。