Processing of hard and brittle materials

Hard and brittle materials are a class of materials that are prone to cracking or chipping during processing, including processable ceramics, quartz, and sapphire. Due to their hardness and brittleness, these materials require special technology and equipment during processing to ensure processing quality and product efficiency.In our CNC machining, we specialize in machining hard and brittle materials, providing high-precision and high-quality machining services. We have advanced CNC processing equipment that can handle the processing needs of various hard and brittle materials, including precision cutting, drilling, grinding and other processes. Our processing equipment is characterized by high speed, high precision and high stability, which ensures that no cracks or chips will occur when processing hard and brittle materials, while being able to achieve processing requirements of complex shapes and precise dimensions.

In addition to CNC processing equipment, we also have more processing equipment, including laser cutting machines, grinders, polishing machines, etc. These equipment can meet the processing needs of different hard and brittle materials, while providing more diversified processing services. Whether it is mass production or customized processing, we are able to provide professional solutions to meet the various needs of our customers.

When processing hard and brittle materials, special processing equipment and processes are required. Common processing methods include grinding, cutting, polishing, etc. In addition, it is necessary to select the appropriate cutting tools and abrasives to ensure that the ideal results can be achieved during the machining process. At the same time, temperature and pressure need to be controlled during processing to avoid cracks or deformation of the material.

Independent water filtration system

Cutting coolant plays a vital role in the machining process. It can not only effectively reduce cutting temperature and extend tool life, but also effectively remove chips and improve the quality of machined surfaces. In order to ensure the effective use of cutting coolant, independent water is used. The filtration system effectively filters impurities and particles in the coolant to ensure the cleanliness and stability of the coolant, thereby improving processing efficiency and product quality.

Cutting cooling uses Q8 Baroni XEPL, which does not contain chlorine and amines and complies with TRGS 611 specifications, which can effectively reduce the harm to the environment and human body. At the same time, it has good cooling performance and lubrication performance, which can ensure the stability and efficiency of the processing process.

Ultrasonic cleaners are an integral part of the cleaning process. We use Alconox Inc.'s Liquinox product, a cleaning agent specifically adapted to the ISO13485 standard. Alconox Inc.'s Liquinox products are highly soluble and easy to rinse, meaning detergent residue can be easily and thoroughly removed during the cleaning process, ensuring part surfaces are clean and germ-free. (More)

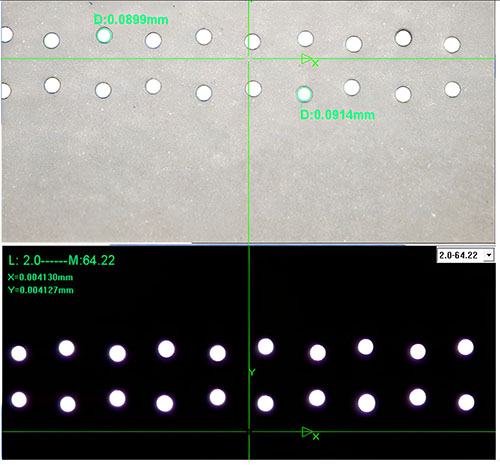

Micro hole drilling (more)

Our company specializes in the processing of hard and brittle materials, has rich processing experience and advanced processing equipment, and is able to provide customers with high-quality processing services. We are good at drilling small holes and can accurately process small holes of various shapes and sizes while ensuring the flatness and accuracy of the processed surface.

- About usLONGYI

- Products

- Advanced Ceramic & Fine Ceramic

- Hard and brittle materials processing

- Contact Us

- News

- Antistatic-ceramic suction cups officially enter the KLA supply system

- Chinese New Year Celebration Announcement

- Since the epidemic of COVID-19 is serious, the production staffs work separately by turns. Delivery time must be affected by process extension.

- Porous Ceramic Vacuum Chuck + Granite Base

- Company relocation notice

- Ceramic characteristics

- Ceramics Gas Tube ASSY

- Die bonder Dispensing Pin 45mil D/B

- Fittings

- Ceramic Ferrule

- Tokyo Weld / Tester / Packaging Machine / Ceramic Index table

- Ceramic Nozzle

- Ceramic Nozzle

- Ceramic Nozzle

- Die bonder Dispensing Pin D/B

- Porous ceramic vacuum chuck

- Advanced Ceramic & Fine Ceramic

|

LONGYI PRECISION TECHNOLOGY CO., LTD.

Address : No. 705, Longxing Road, Chungli District , 32091, Taoyuan, Taiwan

Tel : +886-3-466-6611 Fax : +886-3-466-7722 |

Designed by MIRACLEWeb Design