Advanced Ceramic & Fine Ceramic

Advanced Ceramic & Fine Ceramic

Advanced Ceramic & Fine Ceramic different from traditional ceramic, it made of refined high purity inorganic materials.

Using the chemical formula and physical controlling to make blank. Then molding and sintering make the ceramic's microstructure, chemical, and physical properties reach different status.

After the precision machining, the ceramic will become different products that have different functions.

Advanced Ceramic & Fine Ceramic is widely be used in semiconductor, optoelectronic, biotechnology, and solar energy industries.

Advanced Ceramic & Fine Ceramic 5 features

2. High-Temperature Resistance: Not many materials can withstand high temperatures like ceramic materials, but some Advanced Ceramic & Fine Ceramics can.

3. Abrasion Resistance: Advanced Ceramic & Fine Ceramic's abrasion resistance is absolute. On the other hand, it is fragile.

4. Light Weight: Most Advanced Ceramic & Fine Ceramics are lighter than metal, even can lighter 40%. Due to the light weight, it can reduce machine burden and save energy.

5. Low Coefficient of Friction: Advanced Ceramic & Fine Ceramic can apply on shaft seal and bearing kind of components without smoothing. Because of Advanced Ceramic & Fine Ceramic's low friction coefficient, high compressive strength, and abrasion resistance.

Although Advanced Ceramic & Fine Ceramic have these superior features. But its low toughness and fragility could cause users trouble.

So LONGYI still actively developing higher toughness Advanced Ceramic & Fine Ceramic.

- About usLONGYI

- Products

- Advanced Ceramic & Fine Ceramic

- Hard and brittle materials processing

- Contact Us

- News

- Antistatic-ceramic suction cups officially enter the KLA supply system

- Chinese New Year Celebration Announcement

- Since the epidemic of COVID-19 is serious, the production staffs work separately by turns. Delivery time must be affected by process extension.

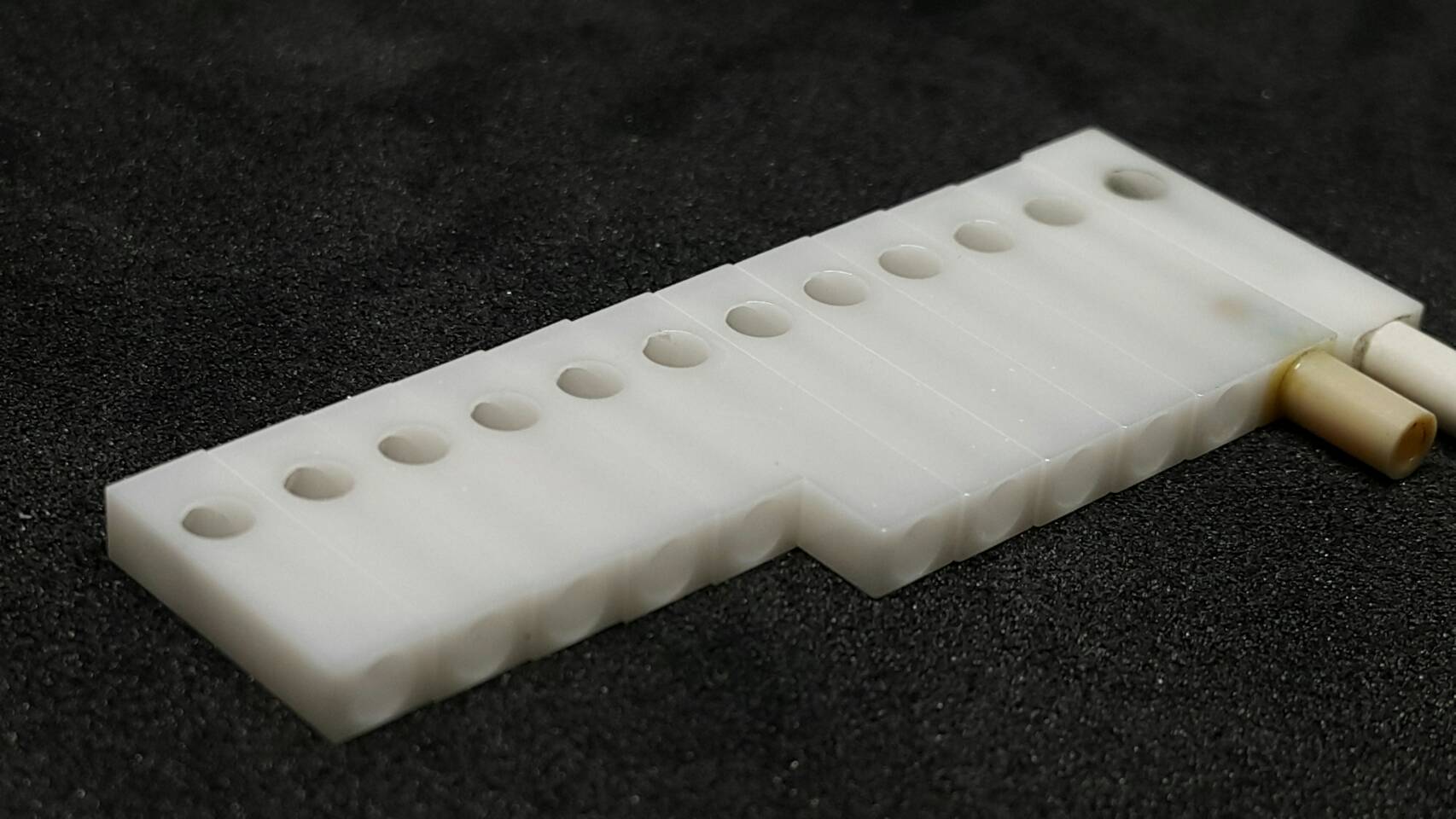

- Porous Ceramic Vacuum Chuck + Granite Base

- Company relocation notice

- Ceramic characteristics

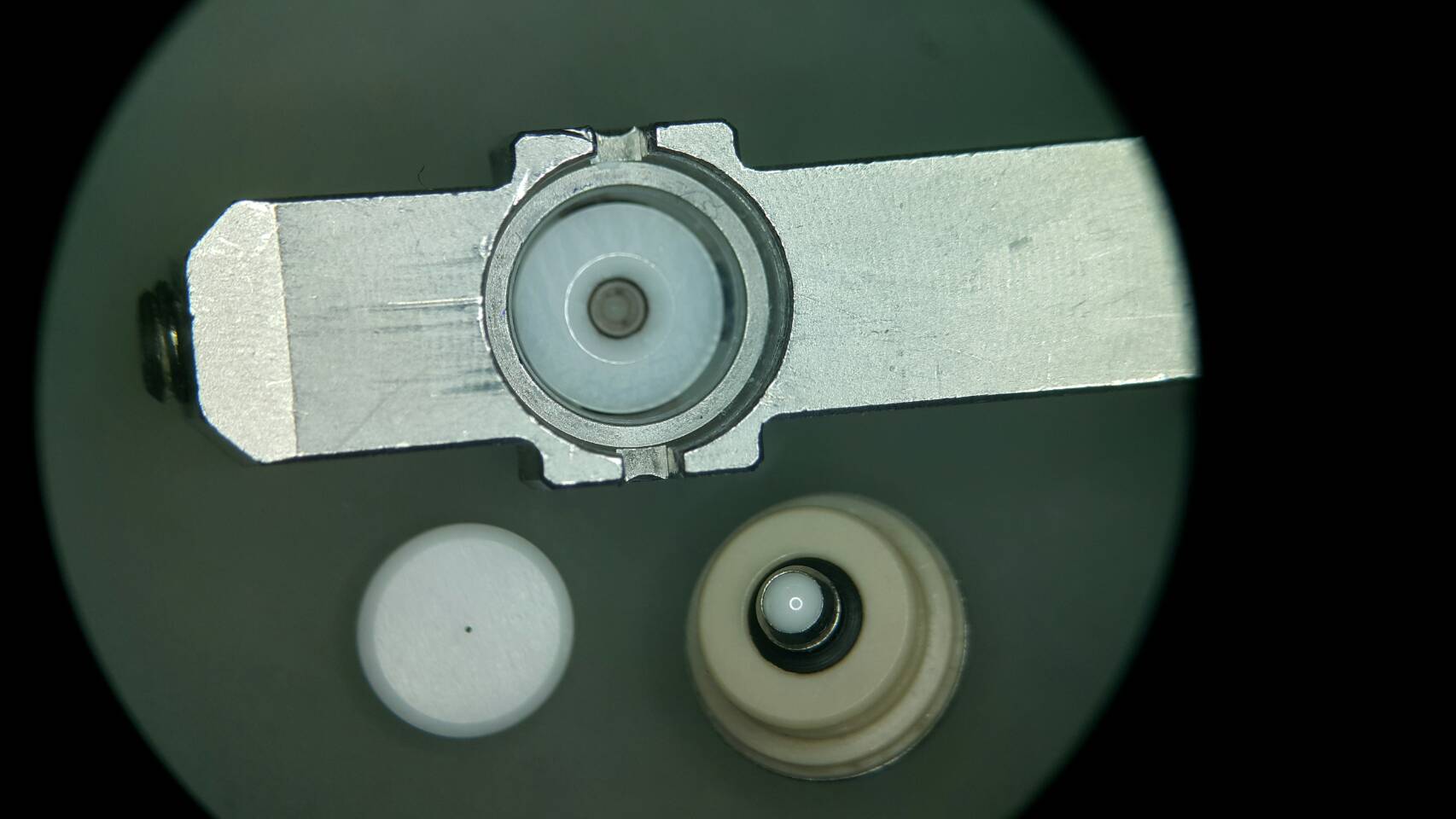

- Ceramics Gas Tube ASSY

- Die bonder Dispensing Pin 45mil D/B

- Fittings

- Ceramic Ferrule

- Tokyo Weld / Tester / Packaging Machine / Ceramic Index table

- Ceramic Nozzle

- Ceramic Nozzle

- Ceramic Nozzle

- Die bonder Dispensing Pin D/B

- Porous ceramic vacuum chuck

- Advanced Ceramic & Fine Ceramic

|

LONGYI PRECISION TECHNOLOGY CO., LTD.

Address : No. 705, Longxing Road, Chungli District , 32091, Taoyuan, Taiwan

Tel : +886-3-466-6611 Fax : +886-3-466-7722 |

Designed by MIRACLEWeb Design